Understanding CNC Capabilities in Swiss Lathes for Sale

Computer Numerical Control (CNC) technology has transformed modern manufacturing by enabling high-precision, automated operations across multiple industries. Swiss lathes, in particular, benefit greatly from CNC integration, allowing workshops to produce complex parts with exceptional accuracy and efficiency. Understanding the capabilities of CNC systems in Swiss lathes is essential for making informed purchasing decisions and optimizing production processes.

Precision and Automation Advantages

A swiss lathe for sale equipped with advanced CNC capabilities offers unparalleled precision and automation. CNC controls allow operators to program multiple machining operations into a single workflow, reducing manual intervention and minimizing the risk of errors. This enables the production of components with tight tolerances, consistent repeatability, and minimal material waste. Automated processes also improve efficiency, allowing machines to operate continuously with reduced downtime.

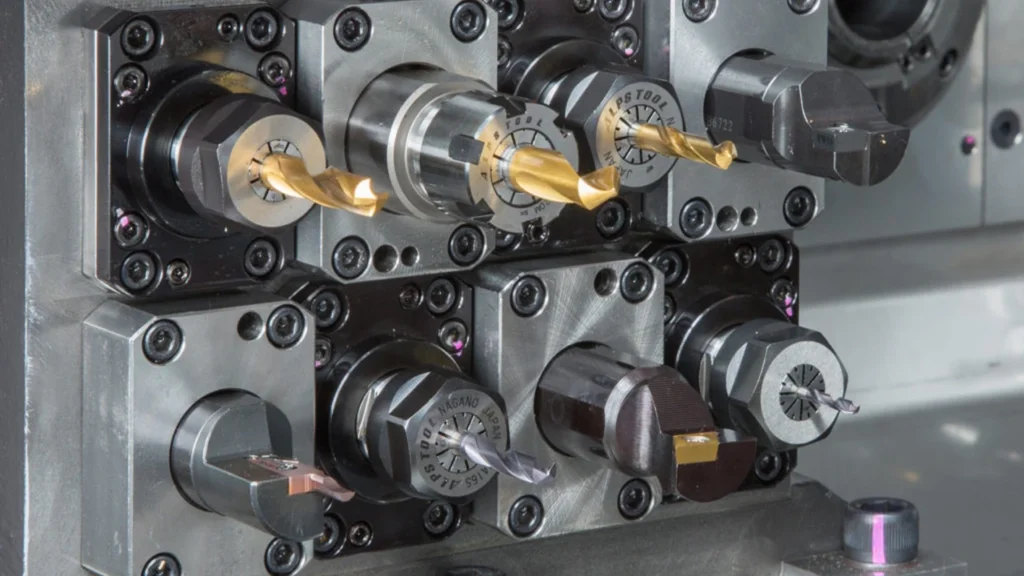

Multi-Axis Machining and Complex Operations

CNC-enabled Swiss lathes often feature multi-axis machining capabilities, which are critical for producing intricate components. With simultaneous control over multiple axes, operators can perform turning, drilling, threading, and milling in a single setup. This reduces the need for multiple machines or repositioning of parts, which enhances both precision and efficiency. Multi-axis CNC operation is particularly valuable in industries such as medical devices, aerospace, and electronics, where complex geometries and tight tolerances are standard.

Programmable Cycles and Customization

One of the most powerful features of CNC-equipped Swiss lathes is programmable cycles. Operators can create, store, and reuse machining programs for recurring parts, ensuring consistent quality across production runs. Customization options within the CNC interface allow adjustments to cutting speed, tool path, feed rate, and other parameters, optimizing each job for material type and desired finish. This flexibility reduces scrap rates and increases throughput while maintaining high-quality output.

Integration with Tooling and Automation Systems

Modern Swiss lathes are often designed to integrate seamlessly with advanced tooling and automation systems. CNC control allows for synchronized operation with automatic bar feeders, robotic handling systems, and part sorting mechanisms. This level of integration improves workflow efficiency and minimizes human intervention, which is especially beneficial in high-volume production environments. The ability to combine CNC precision with automated material handling ensures consistent part quality and faster cycle times.

Software Capabilities and Simulation

CNC systems on Swiss lathes include sophisticated software features such as simulation, error detection, and real-time monitoring. Operators can simulate the entire machining process before executing it, reducing the risk of collisions, tool damage, or part errors. Real-time feedback from the CNC system helps maintain accuracy by compensating for minor deviations and monitoring machine performance. Advanced software also allows for easy updates and integration with enterprise systems, improving overall workshop productivity.

Maintenance and Longevity Considerations

CNC technology also contributes to the longevity of Swiss lathes. Machines equipped with monitoring and diagnostic tools can alert operators to potential issues, enabling proactive maintenance. By maintaining alignment, spindle health, and tool condition, CNC-enabled lathes preserve precision over extended periods. This reduces downtime, lowers maintenance costs, and ensures that the machine continues to deliver high-quality results throughout its service life.

Conclusion

Understanding CNC capabilities in Swiss lathes for sale is essential for manufacturers seeking precision, efficiency, and long-term reliability. From multi-axis machining and programmable cycles to integration with automation systems and advanced software, CNC technology enhances every aspect of production. By selecting a machine that fully leverages these capabilities, workshops can achieve consistent quality, reduced material waste, and optimized workflows, making CNC-enabled Swiss lathes a critical investment for modern manufacturing operations.