How Protective Film Prevents Surface Damage During Storage and Transport

In manufacturing, logistics, and construction industries, maintaining the integrity of surfaces during storage and transport is critical. Scratches, dust, and other forms of surface damage can compromise both the functionality and aesthetic appeal of products. Protective Film has emerged as a highly effective solution for safeguarding materials throughout these processes. Its versatility and reliability make it an essential component in modern supply chain and production workflows.

What is Protective Film?

Protective Film is a thin, adhesive-coated material applied to surfaces to shield them from damage during handling, storage, and transportation. It can be made from polyethylene, polyester, or other durable materials, offering temporary protection without leaving residues on the surface. Many suppliers, including Protective Film, provide films suitable for different applications, thicknesses, and adhesive strengths, ensuring compatibility with a wide range of surfaces, from delicate glass to painted metals.

Preventing Scratches and Abrasions

One of the primary purposes of protective film is to prevent scratches and abrasions during storage and transit. Delicate surfaces such as glass panels, reflective sheets, metal components, and laminated materials are particularly vulnerable to damage from friction, stacking, or handling. Protective film acts as a buffer layer that absorbs minor impacts and prevents direct contact with rough surfaces, helping maintain the product’s visual and functional quality.

Shielding Against Dust and Contamination

During storage and transport, materials are exposed to dust, dirt, and other environmental contaminants that can compromise surface quality. Protective films create a barrier that prevents the accumulation of particles on sensitive surfaces. This is especially important for products such as electronic components, decorative panels, and automotive parts, where even minor contamination can affect performance, finishing, or assembly processes. By keeping surfaces clean, protective films reduce the need for additional cleaning and rework, improving operational efficiency.

Moisture and Chemical Protection

Some protective films are designed to offer resistance against moisture, oils, and other chemical agents. This added protection is critical for surfaces that may be exposed to humid conditions or during the transport of industrial goods through varied environmental conditions. Moisture-resistant protective films prevent corrosion, staining, and other forms of damage, ensuring that products arrive at their destination in optimal condition.

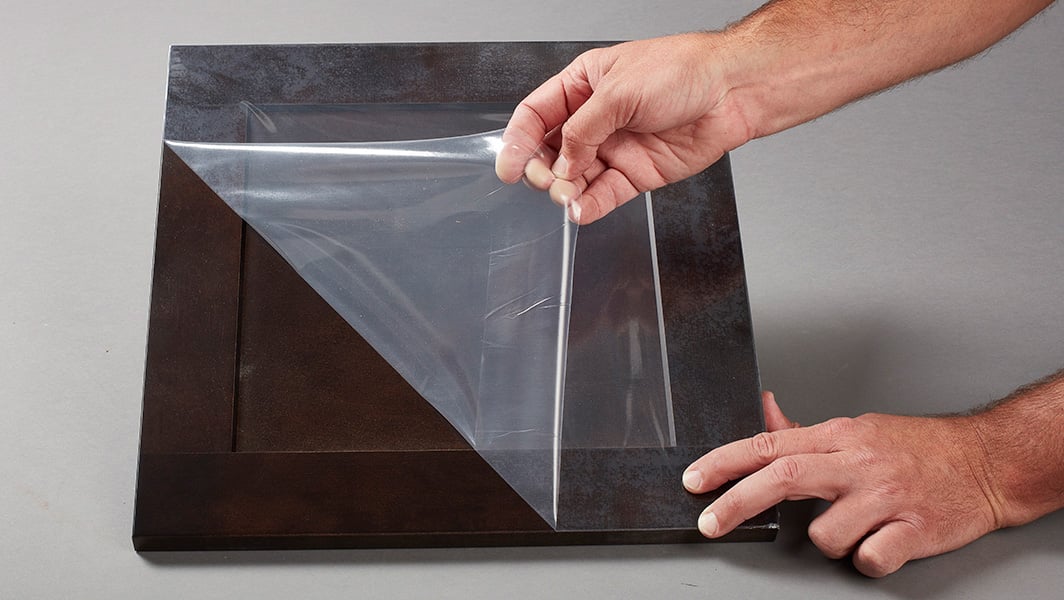

Ease of Application and Removal

Protective films are designed for easy application and removal, making them a convenient solution for storage and transportation needs. They adhere securely during handling yet can be removed without leaving adhesive residues or damaging the surface. This quality ensures that once products reach their final destination, they can be unwrapped quickly and prepared for installation or sale without additional cleaning or refinishing.

Versatile Industrial Applications

Protective films have diverse applications across multiple industries. In construction, they safeguard glass panels, aluminum, and stainless steel surfaces during site installation. In the automotive industry, they protect vehicle panels, dashboards, and interior trim during assembly and shipping. In electronics, protective films prevent scratches and contamination on screens, panels, and sensitive components. Their adaptability makes them an invaluable tool for manufacturers and suppliers aiming to maintain product quality throughout the supply chain.

Cost-Effectiveness and Efficiency

Although protective films represent an additional material cost, their use can result in significant savings by reducing damage-related losses and rework. Maintaining the integrity of surfaces minimizes product rejects, reduces the need for repair or refinishing, and ensures that goods are delivered in pristine condition. This improves customer satisfaction while optimizing operational efficiency, ultimately making protective films a cost-effective solution for industrial protection.

Environmental and Safety Considerations

Modern protective films are designed to meet environmental standards, with many options being recyclable or manufactured from non-toxic materials. They also enhance workplace safety by reducing direct contact with sharp, delicate, or chemically sensitive surfaces. By combining surface protection with environmental and safety considerations, protective films contribute to sustainable and responsible manufacturing practices.

Conclusion

Protective Film is an essential material for preventing surface damage during storage and transport across multiple industries. By protecting against scratches, dust, moisture, and chemical exposure, it ensures products maintain both functional and aesthetic quality. Its ease of application, removability, and versatility make it a practical solution for manufacturers, suppliers, and construction projects alike. Incorporating protective film into storage and transport protocols reduces waste, enhances operational efficiency, and ensures that products arrive in excellent condition, safeguarding both investment and reputation.