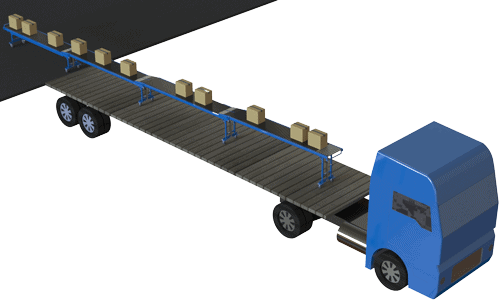

Automation Trends in Vehicle Loading Conveyor Technology

The rise of automation has transformed industrial material handling, significantly improving efficiency, accuracy, and safety. Vehicle loading conveyors, in particular, have benefited from technological advancements that streamline the loading process, reduce labor requirements, and optimize operational workflows. Modern automation trends in vehicle loading conveyor technology are enabling industries to handle higher volumes of materials with greater precision while minimizing operational downtime.

A Vehicle Loading Conveyor is a specialized conveyor system designed to transfer bulk materials or packaged goods directly into trucks or trailers. Automation in these systems allows operators to monitor and control loading processes remotely, ensuring speed, accuracy, and safety. For businesses seeking advanced and reliable solutions, exploring Vehicle Loading Conveyor systems offers access to state-of-the-art designs that integrate automation for maximum operational efficiency across multiple industrial sectors.

Automated Load Monitoring and Control

One of the most significant trends in vehicle loading conveyor technology is the integration of automated load monitoring and control systems. Sensors and weigh systems can detect vehicle presence, monitor material levels, and adjust conveyor speed in real time. This ensures that each truck receives the correct load amount without human intervention. Automated controls reduce the risk of overloading or underloading, improve material distribution, and help operators maintain consistent throughput, especially in high-volume operations.

Integration with Warehouse Management Systems

Modern vehicle loading conveyors are increasingly integrated with warehouse management systems (WMS) and enterprise resource planning (ERP) software. This allows real-time communication between the conveyor system and broader operational workflows. Integration enables automated scheduling, prioritization of vehicle loads, and tracking of material movement from storage to transport. By connecting conveyors to digital management systems, facilities can reduce operational bottlenecks, optimize resource allocation, and improve overall supply chain efficiency.

Telescopic and Adjustable Conveyor Automation

Automation has also been applied to the physical configuration of vehicle loading conveyors. Telescopic and height-adjustable conveyors now feature motorized adjustments that allow the system to extend or retract automatically based on the vehicle’s size or load position. This capability reduces setup time between different truck types and ensures accurate material placement. Automated adjustment minimizes human intervention, reduces the risk of damage, and enhances loading speed, particularly in environments with varying vehicle specifications.

Smart Material Flow Management

Another emerging trend is the use of intelligent material flow management systems. These systems employ sensors, cameras, and software algorithms to monitor the flow of bulk materials or packaged goods along the conveyor belt. Real-time adjustments are made to belt speed, discharge angle, or directional gates to ensure uniform material distribution within the vehicle. Smart material flow management reduces spillage, optimizes truck capacity, and ensures a balanced load, improving transport safety and efficiency.

Predictive Maintenance and Condition Monitoring

Automation trends extend beyond operational controls to system maintenance. Predictive maintenance technologies monitor the condition of conveyor components such as belts, rollers, motors, and drive systems. Sensors collect data on vibration, temperature, and wear patterns, alerting operators to potential issues before they result in breakdowns. Predictive maintenance reduces unexpected downtime, extends equipment lifespan, and minimizes repair costs. Automated condition monitoring ensures that vehicle loading conveyors remain operational and efficient, even under high workloads.

Energy Efficiency through Automated Systems

Modern automated vehicle loading conveyors are designed to optimize energy usage. Variable frequency drives (VFDs) allow the system to adjust motor speeds according to load requirements, reducing energy consumption without compromising performance. Automation systems can also schedule operational times to coincide with peak efficiency periods or integrate with facility energy management systems. These innovations contribute to sustainable operations while lowering operational costs in energy-intensive industries.

Safety Enhancements Through Automation

Automation plays a critical role in enhancing safety for vehicle loading conveyors. Systems can automatically detect unsafe conditions such as belt misalignment, overload, or presence of personnel in hazardous areas. Automated emergency stops, alarms, and protective barriers can be triggered without human intervention, significantly reducing the risk of accidents. By combining operational efficiency with safety automation, modern vehicle loading conveyors protect both personnel and equipment while maintaining high throughput.

Future Outlook

The future of vehicle loading conveyor technology is moving toward fully autonomous systems with advanced analytics and artificial intelligence. Predictive algorithms could optimize load sequences, adjust conveyor operations dynamically, and even coordinate multiple conveyors simultaneously within a distribution or industrial facility. As automation becomes increasingly sophisticated, these conveyors will continue to improve operational speed, accuracy, and safety, allowing industries to handle larger volumes of materials with minimal manual oversight.

Conclusion

Automation trends in vehicle loading conveyor technology are reshaping the way industries handle bulk materials and goods. Features such as automated load monitoring, system integration, telescopic adjustments, smart material flow management, predictive maintenance, energy optimization, and enhanced safety are improving productivity, reducing labor requirements, and extending equipment life. By adopting modern automated vehicle loading conveyors, businesses can optimize their material handling operations, enhance efficiency, and achieve greater reliability in high-volume industrial environments.