A Beginner’s Guide: What Is Offset Printing and How It Works

In the world of printing, achieving high-quality, consistent results is essential for businesses, publishers, and marketers. For those new to printing technologies, understanding What Is Offset Printing and how it functions is a crucial first step. This method remains one of the most widely used techniques in commercial printing due to its efficiency, precision, and ability to produce large volumes of high-quality prints.

Understanding What Offset Printing Is

Offset printing is a technique where an inked image is transferred from a plate to a rubber blanket and then onto the printing surface, typically paper or other materials. Unlike direct printing, this indirect method ensures even distribution of ink and minimizes wear on the printing plates, resulting in sharper images and consistent quality. Many manufacturers and printing professionals rely on solutions like What Is Offset Printing to achieve professional-grade prints for books, packaging, marketing materials, and more.

How Offset Printing Works

1. Plate Preparation

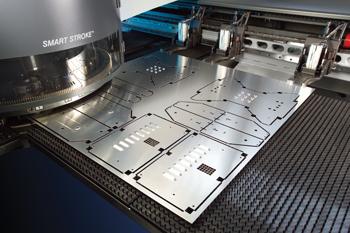

The process begins with the creation of a printing plate, usually made from metal or polymer, which contains the image to be printed. Modern prepress techniques, such as computer-to-plate (CTP) technology, have streamlined this step, allowing for precise and efficient plate production. Each color in the final print typically requires a separate plate.

2. Inking and Image Transfer

Ink is applied to the plate, adhering only to the areas that carry the image. The plate then transfers the ink to a rubber blanket. This intermediate step is key to offset printing, as it prevents direct contact between the plate and the printing surface, reducing wear and ensuring uniform ink application.

3. Printing on the Substrate

The rubber blanket carries the ink onto the substrate, which can be paper, cardboard, or specialty materials. This method produces sharp, high-resolution images and allows for consistent reproduction across large quantities. Offset printing is particularly effective for complex graphics, detailed photographs, and text-heavy designs.

Advantages of Offset Printing

Superior Print Quality

One of the most notable benefits of offset printing is its high-quality output. The indirect transfer method produces clean lines, accurate color reproduction, and fine detail that is difficult to achieve with other printing techniques.

Cost Efficiency for Large Runs

While initial setup costs can be higher due to plate creation and press preparation, offset printing becomes highly economical for large print runs. The per-unit cost decreases as production volume increases, making it an ideal choice for magazines, brochures, packaging, and promotional materials.

Versatility in Materials

Offset printing is compatible with a wide range of substrates, from standard paper to cardboard, plastics, and foils. This versatility enables businesses to use the same printing method for diverse products, maintaining consistent quality across all materials.

Consistent Color Reproduction

Maintaining color accuracy is essential for branding and marketing. Offset printing offers precise control over ink and color application, ensuring that colors remain consistent across all print runs, which is vital for brand integrity and consumer recognition.

Applications of Offset Printing

Offset printing is widely used in numerous industries. In publishing, it produces high-quality books, magazines, and newspapers. In marketing, it is ideal for brochures, flyers, and catalogues. The packaging industry also relies on offset printing for labels, cartons, and other materials that require durable, vibrant, and accurate print. Its ability to handle large volumes efficiently while maintaining quality makes it indispensable for commercial production.

Tips for Beginners

For those new to offset printing, understanding the workflow is essential. Key considerations include selecting the right substrate, ensuring accurate color management, and maintaining presses and plates properly. Working with experienced professionals or service providers can help newcomers achieve high-quality results and maximize the benefits of this printing technique.

Conclusion

In conclusion, What Is Offset Printing and how it works is fundamental knowledge for anyone entering the printing or packaging industry. Its indirect printing method, high-quality output, cost efficiency for large runs, and versatility across materials make it a preferred choice for publishers, marketers, and manufacturers. By understanding the process and advantages of offset printing, beginners can make informed decisions, achieve professional results, and leverage this technology for a wide range of applications in modern production.