Future Trends in Yoga Leggings Production and Materials

The yoga leggings market continues to grow as consumers seek functional, stylish, and sustainable activewear. To stay competitive, brands rely on innovative production techniques and advanced materials. Yoga leggings manufacturers are constantly exploring trends that enhance comfort, performance, and eco-friendliness while meeting evolving consumer demands. Understanding these trends helps brands make strategic decisions and prepare for the future of activewear.

Sustainable and Eco-Friendly Materials

Sustainability is becoming a dominant trend in yoga leggings production. Consumers increasingly prefer eco-friendly fabrics that reduce environmental impact without compromising performance. Materials such as recycled polyester, regenerated nylon, organic cotton, and bamboo fibers are gaining popularity.

A reliable Yoga Leggings Manufacturers can advise brands on integrating these sustainable materials into their collections. Innovations in low-impact dyeing, biodegradable fabrics, and water-saving production processes are helping manufacturers produce leggings that align with environmental values while maintaining stretch, durability, and comfort.

Advanced Fabric Technology

Future trends also focus on enhancing fabric performance through technology. Manufacturers are developing fabrics with improved stretch, moisture-wicking properties, anti-odor treatments, UV protection, and temperature regulation.

Four-way stretch fabrics remain a key innovation, allowing leggings to move freely with the body while maintaining their shape over time. Combined with performance-enhancing treatments, these fabrics create high-quality leggings suitable for intense workouts, hot yoga, or everyday wear.

Customization and Personalization

Consumer demand for unique and personalized activewear is driving trends in customization. Yoga leggings manufacturers are increasingly offering options for custom patterns, color palettes, and designs. Advanced printing techniques, such as digital printing and sublimation, allow precise replication of intricate designs, vibrant graphics, and brand logos.

Customization also extends to functional features, including adjustable waistbands, compression zones, and mesh panels. These innovations help brands differentiate themselves in a competitive market while addressing individual consumer preferences.

Inclusive and Adaptive Sizing

Inclusivity is another trend shaping yoga leggings production. Manufacturers are expanding size ranges and developing leggings that accommodate diverse body types. High-rise, low-rise, long, and cropped options, along with adjustable features, are becoming more common.

Adaptive sizing ensures that leggings provide comfort, support, and a flattering fit for a wider audience. Brands that prioritize inclusivity not only enhance customer satisfaction but also demonstrate social responsibility and a commitment to meeting diverse consumer needs.

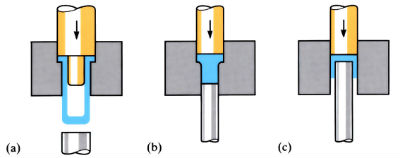

Seamless and Ergonomic Construction

Seamless knitting and ergonomic paneling are increasingly used to improve comfort and fit. Seamless leggings reduce friction, irritation, and pressure points, while ergonomic panels support key muscle groups and enhance flexibility.

Manufacturers are leveraging computer-aided design (CAD) and advanced knitting technologies to produce leggings that conform to body contours while allowing intricate patterns and color combinations. This combination of functionality and style is expected to grow in popularity as consumers seek both comfort and aesthetic appeal.

Smart and Functional Leggings

Technology integration in yoga leggings is an emerging trend. Future designs may incorporate smart textiles that monitor body temperature, track movement, or provide muscle support. Sensors embedded in leggings could offer insights into posture, alignment, or workout intensity, enhancing the yoga experience.

While still in the early stages, smart leggings represent the intersection of performance, health, and technology, providing new opportunities for innovation in activewear.

Efficient Production and Supply Chain Practices

As demand grows, manufacturers are adopting more efficient production and supply chain strategies. Automation, inventory management systems, and advanced quality control protocols help maintain consistency and reduce lead times.

Brands partnering with forward-thinking Yoga Leggings Manufacturers benefit from streamlined operations, sustainable practices, and timely delivery of bulk orders. Optimized production practices ensure high-quality products reach the market without delays or compromised performance.

Conclusion

The future of yoga leggings production is shaped by sustainability, advanced fabric technology, customization, inclusivity, ergonomic design, and smart textile innovations. Yoga leggings manufacturers are embracing these trends to deliver products that combine comfort, performance, and style while addressing environmental and consumer demands. Partnering with experienced Yoga Leggings Manufacturers ensures access to cutting-edge materials, innovative production methods, and efficient supply chain solutions. By understanding and leveraging these trends, brands can create high-quality, market-ready leggings that meet evolving expectations and maintain a competitive edge in the activewear industry.