How to Optimize Workflow Using a Swiss Type Automatic Lathe Machine

Improving workflow efficiency is essential for any modern manufacturing operation, especially in industries where precision and productivity directly influence profitability. Swiss-type lathes are already known for their exceptional accuracy, speed, and ability to produce complex components. However, maximizing their potential requires more than simply running the equipment. Effective planning, proper machine configuration, and disciplined operation all play key roles in ensuring optimal performance.

One of the most effective ways to streamline machining operations is by integrating a swiss type automatic lathe machine into a well-structured workflow. These machines are designed for continuous support of the workpiece and multi-axis functionality, which allows manufacturers to handle high-precision tasks efficiently. When used correctly, they significantly reduce cycle time, enhance repeatability, and improve overall production consistency.

Begin with Clear Production Planning

Optimizing workflow starts with a clear understanding of project requirements. Before programming the machine, operators should analyze part geometry, material specifications, and tolerance demands. Planning also involves determining which operations can be completed within the Swiss machine itself, minimizing the need for secondary processes. Proper planning ensures the machine is used to its full capability and prevents unnecessary delays during production.

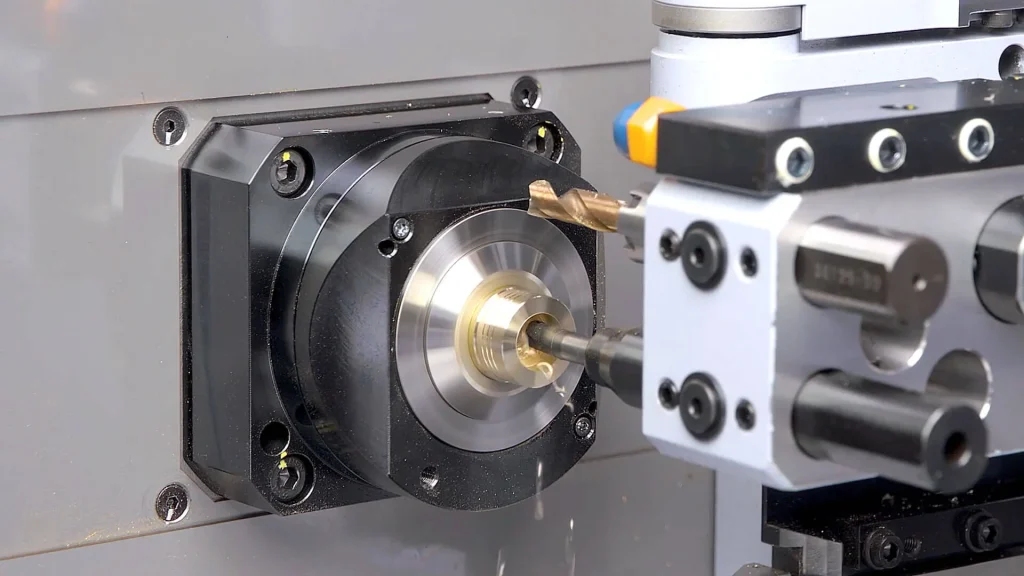

Optimize Tooling Configuration

Tooling plays a crucial role in workflow efficiency. Swiss-type lathes often support multiple tools that operate simultaneously, but the arrangement and selection must be based on the part design. Using high-quality cutting tools with the right coatings and geometries helps maintain accuracy while extending tool life. Additionally, reducing tool change frequency by selecting multifunction tools can improve throughput and reduce downtime.

Make Precise Use of the Guide Bushing

The guide bushing is a defining feature of Swiss-type lathes and greatly influences machining stability. To optimize workflow, operators should ensure correct bushing clearance for each bar diameter and material. Proper adjustment minimizes vibration, improves finish quality, and allows for higher feed rates. This results in smoother operation and reduced cycle times without compromising accuracy.

Leverage Multi-Axis Capabilities

A major advantage of Swiss-type lathes is their ability to perform turning, milling, drilling, and tapping in a single setup. Optimizing workflow means taking full advantage of these multi-axis capabilities. By programming operations to run in parallel where possible, manufacturers can complete complex components faster. This eliminates unnecessary repositioning and handling, which often slow down production on conventional machines.

Implement Effective Coolant and Chip Management

Coolant condition directly impacts machining speed, surface finish, and tool life. Maintaining proper coolant flow and concentration helps support higher cutting speeds while controlling heat generation. Efficient chip removal also contributes to workflow optimization. When chips accumulate near the tooling area, they cause delays and can lead to tool damage. Regular cleaning and effective coolant direction ensure continuous operation with minimal interruptions.

Prioritize Routine Machine Maintenance

Even the most advanced machine cannot perform efficiently without proper maintenance. Consistent lubrication, alignment checks, and cleaning schedules prevent unexpected breakdowns and reduce long-term operational costs. By keeping the machine in optimal condition, manufacturers can maintain high productivity levels, ensuring each work cycle runs smoothly and consistently.

Reduce Setup Time with Standardized Procedures

Setup time can significantly affect workflow, especially in small-batch production. Establishing standardized procedures for tool loading, bar preparation, and program verification reduces reliance on manual adjustments. Using preset tooling systems and developing a clear workflow for machine operators also helps maintain consistency and reduce downtime between jobs.

Utilize In-Process Monitoring

In-process monitoring technologies can greatly enhance workflow efficiency. Measuring tools, spindle load monitoring, and real-time error detection allow operators to identify problems before they impact the final product. By integrating monitoring systems into the workflow, manufacturers can maintain tighter tolerances and ensure consistent output without stopping production for manual inspections.

Enhance Operator Training

Even with advanced automation, operator expertise remains crucial for workflow optimization. Well-trained operators can make better decisions regarding feed speeds, tool changes, and troubleshooting. Investing in training helps ensure that the machine is used to its full potential and reduces the likelihood of avoidable errors or machine downtime.

Conclusion

Optimizing workflow with a Swiss-type automatic lathe requires a combination of proper planning, advanced tooling strategies, machine maintenance, and skilled operation. By utilizing multi-axis capabilities, maintaining ideal guide bushing settings, and implementing streamlined procedures, manufacturers can significantly increase productivity and maintain outstanding part quality. A disciplined approach to coolant management, monitoring, and operator training further enhances efficiency, resulting in a smoother and more reliable machining process.