Key Features to Look for in PU Foaming Machine Manufacturers

Polyurethane (PU) foam plays a vital role in industries such as automotive, furniture, construction, refrigeration, and packaging. As demand for durable and high-performance foam products continues to grow, choosing the right equipment supplier becomes a critical business decision. The performance, efficiency, and reliability of your machinery directly affect production quality and operational profitability. Therefore, evaluating PU Foaming Machine Manufacturers carefully is essential for long-term success.

The global PU foam machinery sector has evolved rapidly with the integration of automation and precision engineering. Businesses searching for dependable PU Foaming Machine Manufacturers must assess more than just pricing. Factors such as technical innovation, engineering expertise, customization capability, and service support play a major role in determining whether a manufacturer can meet both current and future production needs. A well-informed decision reduces operational risks and ensures sustainable growth.

Advanced Technology and Automation Capabilities

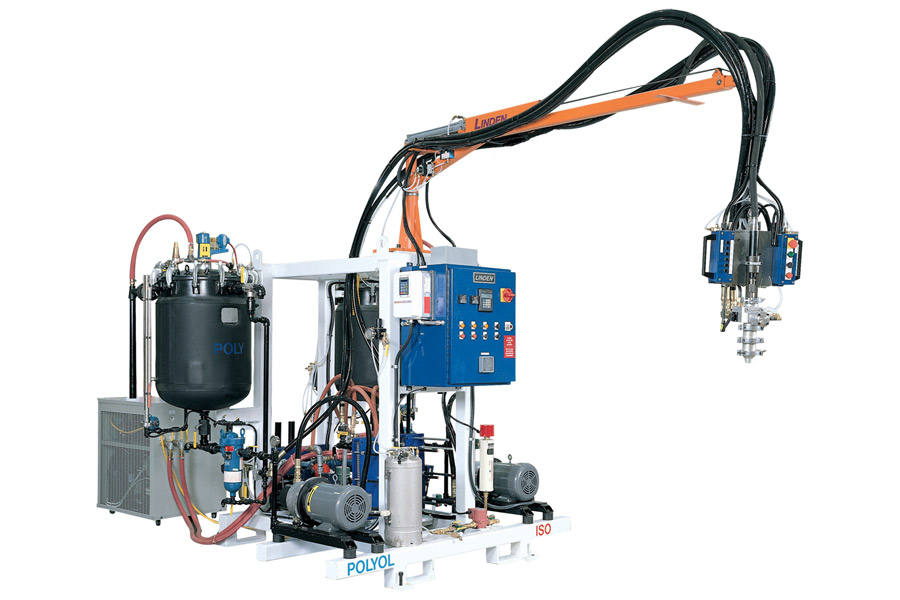

One of the most important features to consider is the level of technology integrated into the machinery. Modern PU foaming machines should include automated control systems, programmable logic controllers (PLC), and user-friendly touch-screen interfaces. Automation enhances precision in chemical mixing, minimizes manual errors, and ensures repeatable production cycles.

Advanced systems may also provide real-time monitoring and remote diagnostics. These features allow operators to track performance data, quickly identify irregularities, and optimize operational efficiency. Manufacturers that consistently invest in research and development are more likely to offer innovative solutions that align with industry advancements.

Precision in Mixing and Metering Systems

Foam quality heavily depends on accurate chemical mixing ratios. Reliable manufacturers design machines with high-precision metering pumps and stable mixing heads to maintain consistent density and structural integrity. Poor mixing can lead to defective foam, uneven expansion, and compromised product performance.

Look for machines that offer precise pressure control, temperature regulation, and stable flow rates. These elements are especially important for industries requiring uniform insulation panels, automotive seating components, and high-resilience foam products.

Customization and Application Flexibility

Every industry has unique production requirements. Whether you need continuous production lines, batch-type systems, high-pressure foaming machines, or low-pressure solutions, flexibility is a key factor. A strong manufacturer should provide customized solutions tailored to your specific capacity, foam formulation, and workspace layout.

Customization options such as adjustable output capacity, specialized molds, and adaptable mixing configurations demonstrate strong engineering capabilities. A manufacturer that understands diverse industrial applications can offer equipment that enhances productivity and minimizes material waste.

Build Quality and Machine Durability

PU foaming machines operate under demanding conditions involving chemicals, heat, and continuous cycles. Durable construction using high-grade steel and corrosion-resistant components ensures longer machine lifespan and reduced maintenance frequency.

Before selecting a supplier, evaluate their quality control standards, certifications, and testing procedures. Manufacturers that adhere to international safety and manufacturing standards typically provide equipment that maintains consistent performance over time. Strong build quality reduces downtime and contributes to a better return on investment.

Energy Efficiency and Environmental Compliance

Energy consumption significantly impacts operational costs in foam production facilities. Modern PU foaming machines should feature energy-efficient motors, optimized heating systems, and improved insulation to reduce power usage. Lower energy consumption not only cuts costs but also enhances sustainability.

Additionally, environmental compliance is increasingly important. Manufacturers that design machines in accordance with environmental regulations help businesses reduce emissions, control chemical handling, and minimize waste. Sustainable machinery supports both regulatory compliance and corporate responsibility goals.

Comprehensive After-Sales Support

After-sales service is one of the most overlooked yet critical factors when choosing a manufacturer. Reliable suppliers provide installation assistance, operator training, maintenance guidance, and readily available spare parts.

Quick technical support minimizes downtime and prevents production losses. Some manufacturers offer preventive maintenance programs and long-term service agreements, ensuring smooth operation throughout the machine’s lifecycle. Strong after-sales support reflects a manufacturer’s commitment to long-term partnerships rather than short-term sales.

Industry Experience and Market Reputation

Experience in PU foam machinery manufacturing plays a crucial role in delivering dependable solutions. Established companies often have extensive project portfolios and a history of serving multiple industries. Reviewing case studies, customer testimonials, and global presence can help assess credibility.

Manufacturers with strong market reputations are more likely to provide consistent quality, timely delivery, and reliable performance. Their expertise enables them to anticipate industry challenges and offer effective solutions.

Integration with Modern Production Lines

Today’s manufacturing facilities rely on seamless system integration. PU foaming machines should be compatible with conveyors, cutting systems, molding units, and automated packaging equipment. Manufacturers that offer turnkey solutions, including layout planning and system integration, add significant value.

Efficient integration reduces manual handling, improves workflow efficiency, and enhances overall production output. This is especially important for businesses planning facility expansion or automation upgrades.

Final Considerations

Selecting the right PU foaming machine manufacturer involves evaluating technological innovation, precision engineering, customization capabilities, durability, and service support. A reliable partner will not only supply high-quality machinery but also provide long-term technical assistance and industry expertise.

By carefully assessing these key features, businesses can invest confidently in equipment that ensures consistent foam quality, operational efficiency, and sustainable growth in a competitive market.