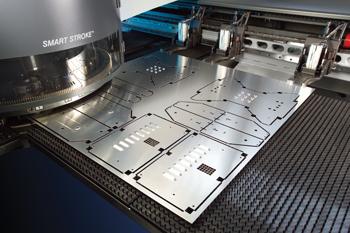

Safety Guidelines for Using Press Punch Machines

Press punch machines are widely used in metal fabrication industries to cut, shape, and perforate sheet metals efficiently. While these machines improve productivity and precision, they also pose significant safety risks if not operated correctly. Ensuring the safety of operators and maintaining a secure working environment is critical to preventing accidents and protecting both personnel and equipment. Understanding and following safety guidelines is essential for anyone working with a press punch machine.

Proper Training and Operator Awareness

The foundation of safety when using a press punch machine is proper training. Operators must understand how the machine functions, including the mechanical, hydraulic, or servo-driven components, and how different metals and thicknesses affect operation. Familiarity with emergency stop systems, control panels, and safety interlocks is crucial. Many Press Punch Machine models feature automated safety systems, but these should not replace fundamental knowledge of machine operation. Operators must be aware of potential hazards, such as pinch points, moving parts, and sharp edges, and should receive continuous training to keep safety skills up to date.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment (PPE) is essential for preventing injuries. Operators should always wear safety glasses or face shields to protect against flying debris, metal shavings, and sparks. Gloves designed for handling sheet metal can prevent cuts, while ear protection reduces the risk of hearing damage from high-decibel machine operation. Steel-toed footwear is recommended to protect feet from heavy sheets or tools that may fall during operation. Ensuring that clothing is fitted and free from loose sleeves or jewelry prevents entanglement in moving parts.

Machine Inspection and Maintenance

Regular inspection and maintenance of the press punch machine are key components of workplace safety. Operators should check for wear on punches, dies, and moving parts before each use. Hydraulic fluid levels, lubrication points, and electrical connections should be inspected according to the manufacturer’s maintenance schedule. Ensuring that all safety guards, light curtains, and interlock systems are functional reduces the risk of accidents. Preventive maintenance also extends the lifespan of the machine and maintains operational efficiency while minimizing downtime.

Safe Operating Procedures

Adhering to safe operating procedures is critical when using a press punch machine. Operators should always ensure that workpieces are properly positioned and securely clamped before initiating a punch. Hands and fingers should never be placed near the punch area during operation, and tools should be used to adjust or reposition materials when necessary. Operators should avoid reaching over the machine while it is running and should remain alert to any unusual noises or vibrations that could indicate mechanical problems. Using the correct dies and settings for each material type also ensures safe and accurate punching.

Emergency Stops and Safety Interlocks

Modern press punch machines are equipped with emergency stop buttons, safety interlocks, and light curtains to prevent accidents. Operators should familiarize themselves with the location and function of these safety features. In the event of a jam, misalignment, or other hazard, stopping the machine immediately can prevent injury and equipment damage. Safety interlocks prevent operation when guards are open or improperly positioned, ensuring that the machine cannot be activated in unsafe conditions. Regular testing of these systems ensures they remain effective and reliable.

Ergonomics and Workstation Safety

Proper workstation setup contributes to operator safety and efficiency. The machine should be positioned at a comfortable working height to reduce strain and fatigue. Adequate lighting ensures that operators can see the workpiece clearly, while a clean and organized workspace minimizes tripping hazards or accidental contact with moving parts. Anti-fatigue mats may help reduce strain during long shifts, improving both safety and productivity.

Handling Material and Waste

Proper handling of sheet metal and scrap is important for safety. Sharp edges and offcuts can cause cuts or puncture wounds. Operators should use designated containers for scrap metal and maintain a clear area around the machine to prevent slips and trips. Using tools such as tongs, clamps, or magnetic lifters to handle heavy or sharp sheets reduces the risk of injury.

Conclusion

Ensuring safety when using a Press Punch Machine requires a combination of proper training, personal protective equipment, machine inspection, safe operating procedures, and emergency preparedness. Regular maintenance, awareness of hazards, and adherence to manufacturer guidelines significantly reduce the risk of injury and protect both operators and equipment. By implementing these safety guidelines, manufacturers can create a secure working environment while maintaining high productivity and precision in metal fabrication operations.