Steel Pipe End Cap: Functions, Types, and Common Applications in Piping Systems

In piping systems, every component plays a critical role in ensuring safety, efficiency, and reliability. Among these components, the steel pipe end cap stands out as a simple yet essential fitting used across industries. Whether in construction, water supply, oil and gas, or chemical processing, end caps are designed to close off the ends of pipes, providing a secure and leak-proof seal. Their durability and versatility make them indispensable in projects that require strong and long-lasting piping solutions.

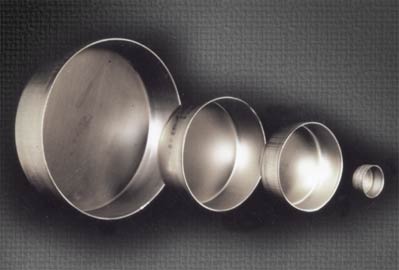

What is a Steel Pipe End Cap?

A steel pipe end cap is a specialized fitting placed at the end of a pipe to block off the opening. Its main function is to stop the flow of liquids, gases, or other materials within the pipeline. End caps can be welded, threaded, or mechanically fitted depending on the type of piping system.

High-quality Steel Pipe End Cap products are manufactured to meet the needs of various industries, offering strong resistance to pressure, corrosion, and environmental stress. Their role is not only functional but also protective, helping to maintain the integrity of the entire piping network.

Functions of a Steel Pipe End Cap

The primary functions of pipe end caps include:

- Sealing the Pipe: Prevents the escape of fluids or gases, ensuring system integrity.

- Protection: Shields the open end of the pipe from dust, moisture, and contaminants during storage or transportation.

- Pressure Resistance: Withstands internal pressures, making it suitable for high-pressure applications.

- Structural Support: Helps maintain the strength of the pipeline by providing closure at its ends.

- Safety Assurance: Minimizes the risk of leaks, which can lead to operational hazards or environmental damage.

Types of Steel Pipe End Caps

End caps are available in different designs to match diverse applications. Some of the most common types include:

- Welded End Caps: Permanently attached to pipes, ideal for applications where the pipeline is not expected to be reopened.

- Threaded End Caps: Allow for easy installation and removal, commonly used in systems requiring periodic maintenance.

- Butt-Weld End Caps: Provide a smooth and seamless connection, often used in critical industries like oil, gas, and chemicals.

- Dome-Shaped End Caps: Designed to resist higher pressures due to their curved shape.

- Protective Caps: Temporary solutions to protect pipes during shipping and storage.

The choice of end cap type depends on the operational requirements, such as pressure levels, accessibility, and environmental conditions.

Applications in Piping Systems

Steel pipe end caps are widely used across industries due to their reliability and strength. Common applications include:

- Oil and Gas Pipelines: Essential for closing off sections of pipelines during construction or repair.

- Water Supply Systems: Used to terminate pipelines safely and prevent leaks.

- Chemical Processing Plants: Provide secure closures in environments handling corrosive or hazardous materials.

- Construction Projects: Offer temporary or permanent sealing for pipes in building frameworks.

- Transportation and Storage: Protect the integrity of pipes during movement and storage by covering open ends.

These applications highlight the versatility of steel end caps in both permanent and temporary scenarios.

Advantages of Using Steel Pipe End Caps

The benefits of incorporating steel pipe end caps in piping systems are numerous:

- Durability: Resistant to corrosion, wear, and extreme environmental conditions.

- Leak Prevention: Ensures a secure seal, protecting against costly leaks or failures.

- Cost Efficiency: Reduces long-term maintenance and replacement expenses.

- Flexibility: Available in multiple types and sizes for different applications.

- Compliance: Designed to meet industry standards, ensuring safety and reliability.

Importance in Modern Infrastructure

Steel pipe end caps are a small yet critical part of modern infrastructure projects. Their role in protecting pipelines, preventing leaks, and ensuring structural safety contributes to the long-term success of industries worldwide. From residential water supply systems to high-pressure oil pipelines, these fittings ensure that systems operate effectively and securely.

Conclusion

The steel pipe end cap is more than just a closure; it is a vital component that guarantees the safety, performance, and reliability of piping systems. By offering robust sealing, protection, and adaptability, it supports a wide range of industrial applications. As infrastructure continues to expand, the use of high-quality steel pipe end caps will remain essential for achieving efficiency and long-term durability in piping networks.