Water Soluble Film Packaging Machines for Detergent Applications

Water soluble films have become a game-changer in the detergent industry, enabling convenient single-dose packaging for laundry pods, dishwasher tablets, and liquid detergent capsules. These films dissolve completely in water while maintaining strength during handling, providing a mess-free and eco-friendly solution for consumers. However, achieving precise and consistent packaging requires specialized machinery capable of handling delicate films without damage. Water soluble film packaging machines are designed to meet these unique requirements, ensuring efficiency, accuracy, and high-quality output in detergent production lines.

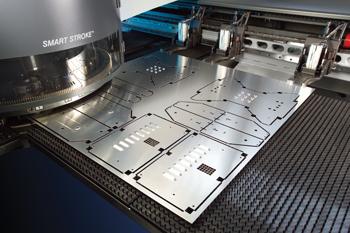

A modern Water Soluble Film Packaging Machine for detergent applications integrates advanced components such as automated film feeding, accurate dosing units, precise sealing, and real-time monitoring. These features allow manufacturers to produce large volumes of detergent pods or sachets with consistent size, weight, and integrity. By automating critical steps, the machine reduces manual handling errors, minimizes material waste, and ensures that every package meets both consumer and regulatory standards.

Precision Film Feeding Systems

The first step in packaging detergent pods or sachets is feeding the water soluble film into the machine. Proper film handling is essential, as excessive tension, misalignment, or friction can tear the delicate material. Feeding systems in these machines use rollers, guides, and tension controllers to maintain smooth, uniform movement of the film.

Sensors continuously monitor film alignment and tension, automatically making adjustments to prevent damage. This precise feeding system allows for consistent formation of detergent pods, maintaining the correct shape and volume for each unit while minimizing waste and downtime.

Accurate Dosing for Detergent Products

Detergent applications require precise dosing to ensure that each pod or capsule contains the correct amount of detergent powder or liquid. Water soluble film packaging machines use volumetric or gravimetric dosing units that deliver consistent quantities into the film pockets.

For liquid detergents, pumps or metering systems provide controlled flow, while powdered detergents use hoppers and conveyors designed to prevent clogging or uneven distribution. Accurate dosing prevents overfilling or underfilling, maintains package integrity, and guarantees consumer satisfaction with every use.

Sealing Technology for Water Soluble Films

Sealing is a critical component of detergent packaging, as leaks or weak seals can compromise product quality. Advanced machines use heat, pressure, or ultrasonic sealing to bond the water soluble film edges without damaging the material.

Adjustable sealing jaws and precise temperature controls ensure that each pod or sachet is consistently sealed. Some machines employ dual-seal or multi-jaw systems to strengthen the package further, reducing the risk of leaks during transport or storage. This level of control is especially important for liquid detergents, where improper sealing could result in spillage or premature dissolution.

Cutting and Separation Mechanisms

After the pods or sachets are formed and sealed, cutting mechanisms separate individual units from the continuous film roll. Precision cutting is necessary to maintain uniform package size and shape while avoiding tears or deformities.

Advanced machines integrate cutting systems with the sealing unit to streamline production, reduce cycle time, and minimize the risk of defects. Proper cutting also ensures that packaging aligns with automated filling and packaging lines for secondary processing.

Automation and Control Systems

Modern detergent packaging machines include sophisticated automation and control features to enhance efficiency and maintain quality. Programmable logic controllers (PLCs) and touch-screen interfaces allow operators to adjust film feed rates, dosing quantities, sealing temperature, and cutting dimensions.

Integrated sensors and monitoring systems provide real-time feedback, detecting issues such as misaligned film, improper fills, or weak seals. Automatic adjustments reduce downtime, improve throughput, and maintain consistent quality across large production runs, which is essential for meeting high consumer demand.

Auxiliary Features for Efficiency and Reliability

Water soluble film packaging machines for detergent applications often include additional components to improve reliability and reduce maintenance requirements. Moisture control systems prevent premature softening of the film, while conveyors and air knives guide pods gently through the production line. Cooling units can stabilize heat-sealed areas, and automated waste removal systems help maintain a clean, efficient operation.

These auxiliary features protect the delicate film and ensure that detergent pods or sachets retain their shape, integrity, and solubility until use.

Maintenance and Longevity

Regular maintenance is essential for keeping water soluble film packaging machines operating efficiently. Cleaning film guides, lubricating moving parts, inspecting sealing jaws, and monitoring electrical components can prevent mechanical issues and reduce downtime.

Operators trained in proper maintenance techniques can quickly identify potential problems, ensuring continuous production and consistent pod quality. Preventive care helps extend the machine’s lifespan while maintaining high output standards.

Conclusion

Water soluble film packaging machines are essential for producing detergent pods, capsules, and sachets efficiently and reliably. By combining precise film feeding, accurate dosing, controlled sealing, and advanced monitoring, these machines ensure that delicate water soluble films are handled without damage. Automation and auxiliary features enhance production speed, consistency, and product quality, while proper maintenance ensures long-term reliability. Investing in a high-quality water soluble film packaging machine enables detergent manufacturers to meet consumer demand, reduce waste, and maintain safe, eco-friendly, and convenient packaging solutions.