Water Soluble Packaging Machines for Pharmaceutical and Medical Use

Water soluble packaging machines have become increasingly important in the pharmaceutical and medical industries. These machines are designed to handle delicate, moisture-sensitive films that dissolve completely in water, offering a safe, convenient, and environmentally friendly way to package medications, disinfectants, and other medical products. As healthcare and pharmaceutical sectors continue to prioritize hygiene, accuracy, and patient safety, water soluble packaging machines are playing a critical role in ensuring reliable and efficient packaging solutions.

Importance of Water Soluble Packaging in Healthcare

The pharmaceutical and medical industries have stringent requirements for product safety, contamination prevention, and dosage accuracy. Water soluble films offer a unique advantage in this context by creating single-dose packaging that dissolves completely when in contact with water. This eliminates the risk of leftover packaging waste, reduces exposure to potentially hazardous chemicals, and ensures precise dosing.

For hospitals, clinics, and healthcare facilities, using pre-measured doses in water soluble packaging minimizes handling risks and improves operational efficiency. Products such as powdered medications, disinfectants, and cleaning agents can be packaged in a format that is easy to use, hygienic, and safe for both medical staff and patients.

Key Features of Pharmaceutical Water Soluble Packaging Machines

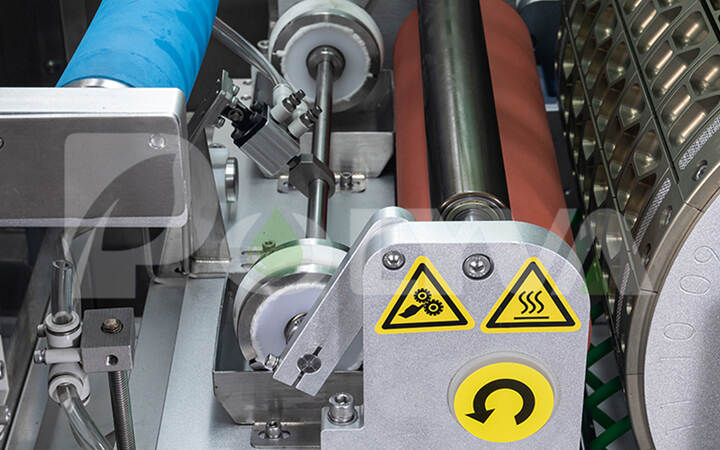

A modern Water Soluble Packaging Machine designed for pharmaceutical and medical use integrates precision dosing, sealing, and cutting mechanisms to maintain high-quality standards. These machines are engineered to handle sensitive films without tearing or premature dissolution. Advanced systems allow for precise filling of powders, granules, gels, and liquids, ensuring consistent dosage for every unit.

Environmental control is also a critical feature for pharmaceutical applications. These machines often include temperature and humidity regulation to protect water soluble films from moisture, which could compromise product integrity. Automation and monitoring systems allow for real-time adjustments and quality checks, further ensuring that each package meets the strict regulatory requirements of the healthcare sector.

Applications in Pharmaceutical Packaging

Water soluble packaging machines are widely used for pharmaceutical products that require precise dosing and high hygiene standards. Powders, granules, or capsules intended for oral consumption or medical treatment can be individually packaged in water soluble films. Single-dose packaging ensures patients receive the correct quantity of medication, reducing the risk of errors and improving treatment outcomes.

Additionally, liquid medications and gels can be packaged in water soluble pouches, which are convenient for patients and caregivers. This is particularly beneficial in hospitals or home care settings where accurate dosing and ease of administration are critical. The machine’s precise filling and sealing functions prevent leakage and contamination, maintaining product quality throughout transportation and storage.

Applications in Medical Disinfectants and Cleaning Agents

The use of disinfectants and cleaning agents in medical environments requires careful handling due to their chemical composition. Water soluble packaging allows these products to be pre-measured and safely delivered to healthcare facilities. Hospitals, laboratories, and clinics benefit from single-dose packs that reduce handling risks and ensure proper application. Water soluble packaging machines produce uniform units with secure seals, supporting safe and efficient use of potentially hazardous substances.

Safety and Compliance Benefits

Safety and compliance are major drivers for adopting water soluble packaging in the medical and pharmaceutical industries. These machines reduce the risk of operator exposure to chemicals, powders, and active pharmaceutical ingredients. Automated systems minimize human contact, improving workplace safety and maintaining hygienic conditions.

In addition, water soluble packaging helps manufacturers comply with regulatory standards for pharmaceutical products, including dosage accuracy, contamination control, and environmental safety. The elimination of residual packaging material also aligns with global sustainability initiatives, offering both operational and ecological benefits.

Maintenance and Operational Considerations

Maintaining water soluble packaging machines for pharmaceutical use is critical for reliable performance. Regular cleaning, lubrication, and inspection prevent downtime and ensure the machine operates at optimal efficiency. Humidity and temperature controls must be monitored consistently to protect sensitive films. Operators should be trained in proper handling and maintenance procedures to ensure that the machine continues to deliver precise, high-quality packaging.

Future Trends in Pharmaceutical Water Soluble Packaging

The demand for water soluble packaging in the healthcare sector is expected to grow as patient-centric solutions and eco-friendly packaging become more important. Advancements in film materials, automation, and quality monitoring will allow machines to handle a broader range of pharmaceutical products efficiently. Integration with smart manufacturing systems and real-time data tracking will enhance operational efficiency, reduce errors, and support regulatory compliance.

Conclusion

Water soluble packaging machines play a vital role in pharmaceutical and medical applications by ensuring accurate dosing, safe handling, and sustainable packaging. Their ability to package powders, liquids, gels, and disinfectants in single-dose water soluble films improves hygiene, reduces contamination risks, and enhances operational efficiency. With precise filling, secure sealing, and environmental controls, these machines meet the high standards required in healthcare. By investing in advanced water soluble packaging technology, manufacturers and medical facilities can ensure patient safety, maintain regulatory compliance, and support sustainable practices in the medical and pharmaceutical industries.